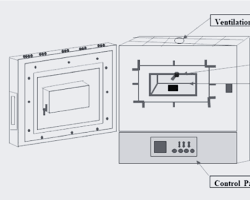

1.Muffle Chamber

A muffle furnace is a high-temperature laboratory furnace used for burning, ashing, sintering, or heat-treating samples. It’s widely used in chemistry, ceramics, metallurgy, and material science labs.Below is a list of Muffle furnace parts and functions:

Function: The insulated compartment where samples are placed for heating. It isolates the sample from direct contact with heating elements or combustion gases, ensuring uniform heating and preventing contamination.

2. Heating Elements:

Function: Typically made of materials like Kanthal or ceramic, these generate heat through electrical resistance. They surround the muffle chamber to provide consistent, high-temperature heating (up to 1800°C in some models).

3.Insulation (Refractory Material):

Function: High-temperature-resistant materials (e.g., ceramic fibre or firebrick) line the furnace to minimize heat loss, maintain internal temperature, and protect the outer structure from extreme heat.

4. Thermocouple:

Function: A temperature sensor (e.g., Type K or Type S) that measures the chamber’s internal temperature and sends data to the controller for precise temperature regulation.

5.Temperature Controller:

Function: A digital or analog system that allows users to set, monitor, and regulate the furnace temperature. Advanced models include programmable controllers for ramping and soaking cycles.

6. Outer Casing:

Function: The external metal housing (often stainless steel) protects internal components, ensures structural integrity, and provides safety by shielding users from high temperatures.

7. Door with Safety Interlock:

Function: The insulated door provides access to the muffle chamber. The safety interlock cuts power to the heating elements when the door is opened, preventing burns or accidents.

8. Exhaust Vent/Port:

Function: Allows the release of fumes, gases, or combustion byproducts from the chamber, ensuring a safe working environment and preventing pressure build up.

9. Control Panel:

Function: Houses the user interface, including temperature controls, timers, and indicators for power, temperature, and operational status.

10. Power Supply Unit:

Function: Supplies electrical power to the heating elements and control systems, typically designed for specific voltage and current requirements.

| Muffle Size mm | Heater Load KW | Temperature Controller |

| 100x100x225 | 2.5 | PID |

| 125x125x250 | 3.0 | PID |

| 150x150x300 | 4.0 | PID |

| 200x200x300 | 5.0 | PID |

| 175x175x450 | 6.0 | PID |

| Muffle Size mm | Heater Load KW | Temperature Controller |

| 125x125x250 | 4.0 | PID |

| 150x150x300 | 6.0 | PID |

| 200x200x300 | 9.0 | PID |

| 175x175x450 | 12.0 | PID |

1.Proximate Analysis: They facilitate the analysis of moisture, volatile compounds, and other components by heating samples under controlled conditions, aiding in the characterization of food composition.

2.Microbiological Testing: Muffle furnaces are used to sterilize equipment or glassware by subjecting them to high temperatures, ensuring contamination-free environments for microbial analysis.

3. Research and Development: In food R&D, muffle furnaces are used to study the thermal stability of ingredients, simulate cooking processes, or develop new food products by analyzing how ingredients behave under high temperatures.

4. Heavy Metal and Contaminant Testing: They assist in preparing samples for heavy metal or contaminant analysis by ashing organic material, leaving behind residues for further chemical analysis.

5.Quality Control of Additives: Muffle furnaces help test the purity of food additives or ingredients (e.g., salts, minerals) by removing impurities through high-temperature processing.

Accumax India is a prominent Muffle Furnace manufacturer with a robust brand name in testing equipment. Accumax India offers laboratory as well as industrial muffle furnaces of high quality with features of the new generation like accurate temperature control, energy-saving, and robust construction.

Looking for the best muffle furnace price?

Get high-quality,precision-controlled muffle furnaces at competitive rates from Accumax India. Contact us today for a customized quote.